How To Remove And Disassemble The Crankcase On Your 97-01 Honda CR250

- 8mm Socket

- 14mm Socket

- 22mm Socket

- Mallet

- Wood Blocks

- Towels

- Big Hammer

- Plastic Scraper → https://amzn.to/40dl2Q1

- Flat Razor

- Dremel with Sanding Disc → https://amzn.to/407t6l3

- WD40

- Paper Towels

- Safety Glasses → https://bulltru.com

The only specialty tool you will need is a case splitter, and you can get one here. → https://amzn.to/429iNjg

Pre-Service Notes

- Put your bike on a sturdy stand and drain oil and coolant.

- I recommend opening the Bottom End Service Specifications in a new tab for easy reference.

- If you need parts and tools, make sure to buy them here!

- Pictures with captions are after the steps below.

- If you need any help, lp don’t hesitate to ask!

Bottom End Removal

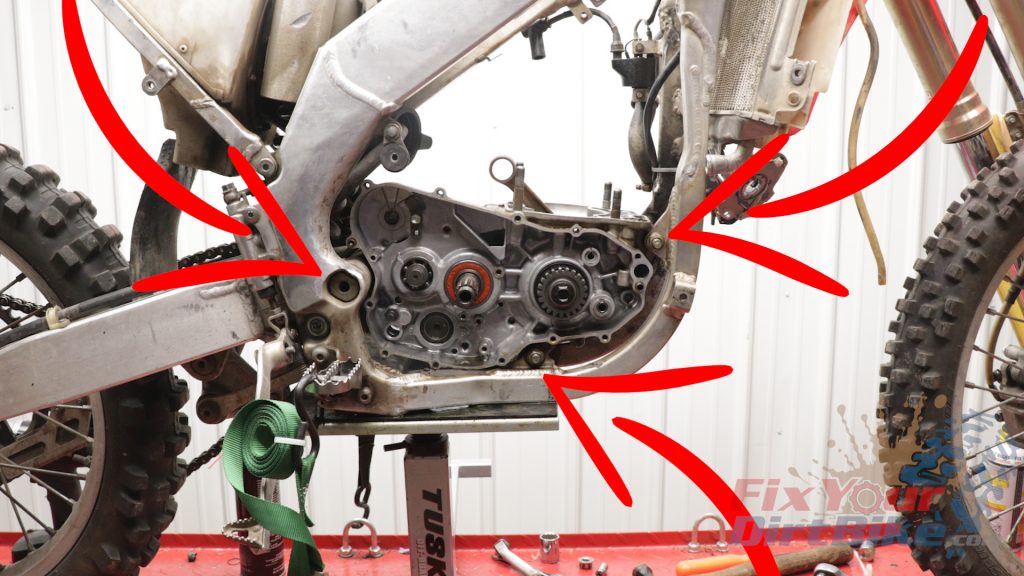

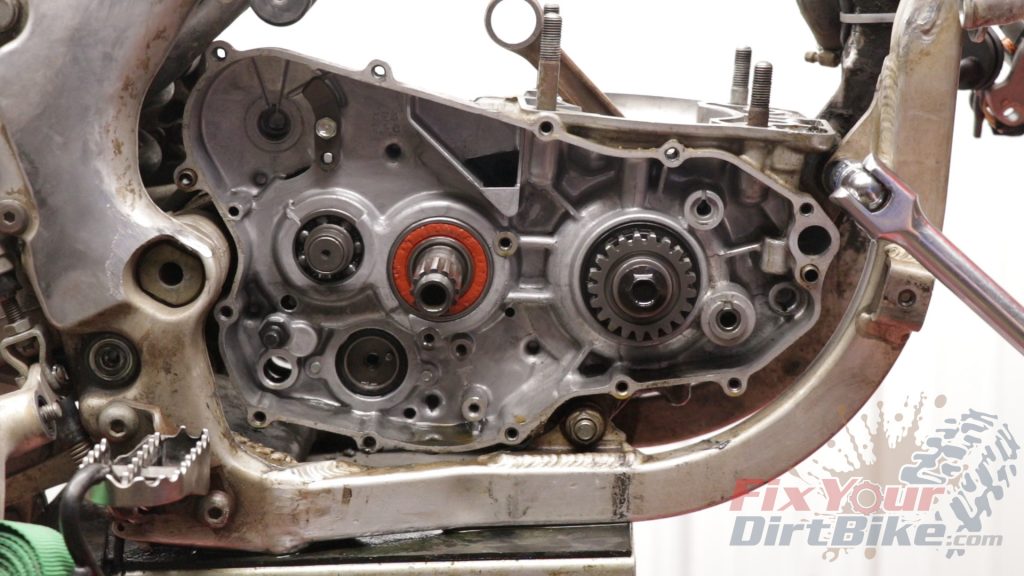

- Three bolts attach the bottom end to the frame, two mounting bolts, and the swingarm pivot shaft.

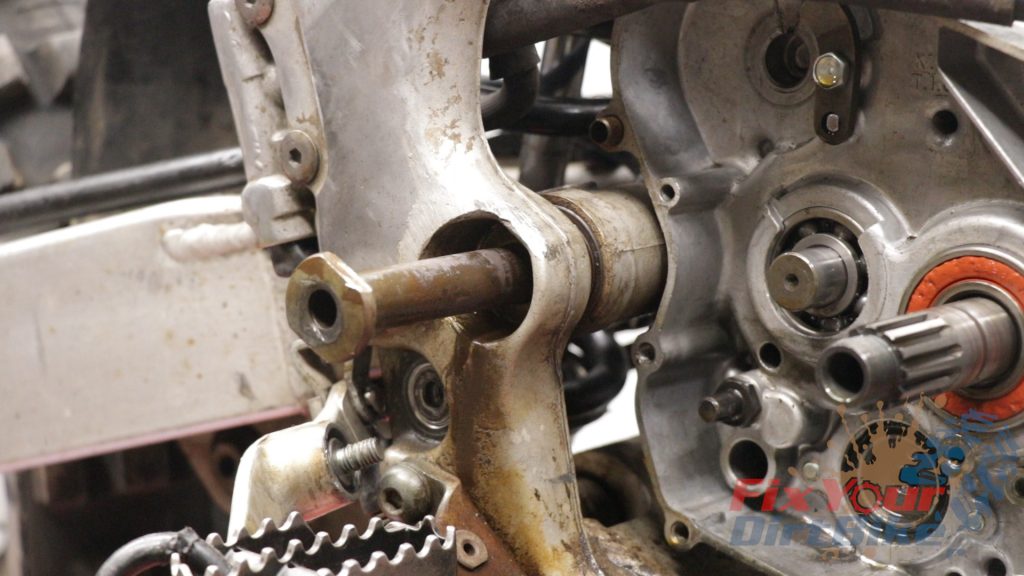

- Start by removing the swingarm pivot shaft first because I have never had one come out easy.

- You may find yourself with a seized shaft. The only thing you can do is hose it down with anti-seize, wait, hit the bolt with the biggest hammer you have, and repeat as needed.

- You will need a new pivot bolt, but they are not too expensive.

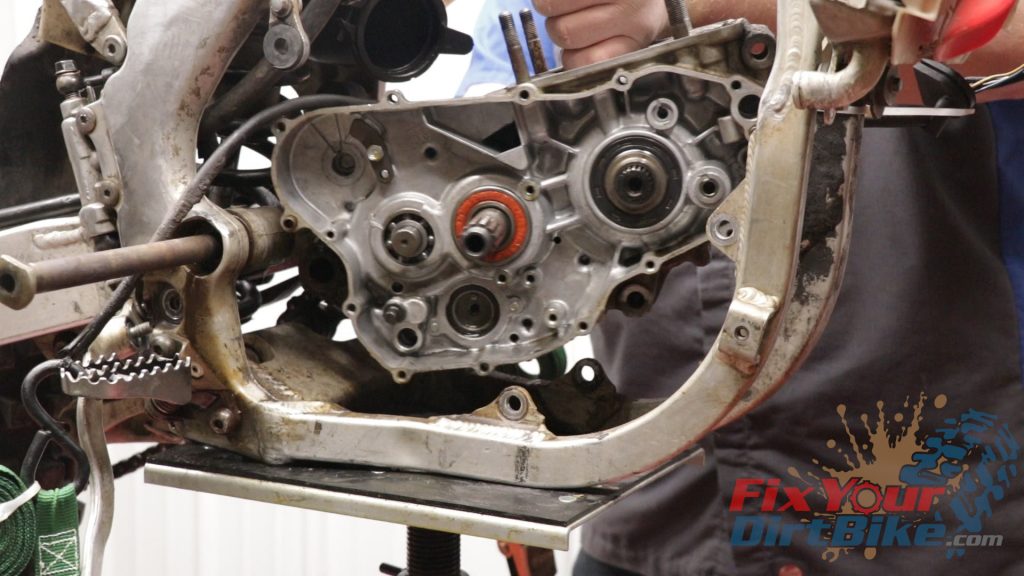

Remove the two lower mounting bolts and keep track of their installation installation direction. - Remove the engine from the frame. The swingarm may be resting on the rear of the case, so lift the front end first and give it a jiggle. But do not lift the case by the crankshaft like this impatient idiot.

- With the case removed, clean and inspect the frame.

Crankcase Disassembly

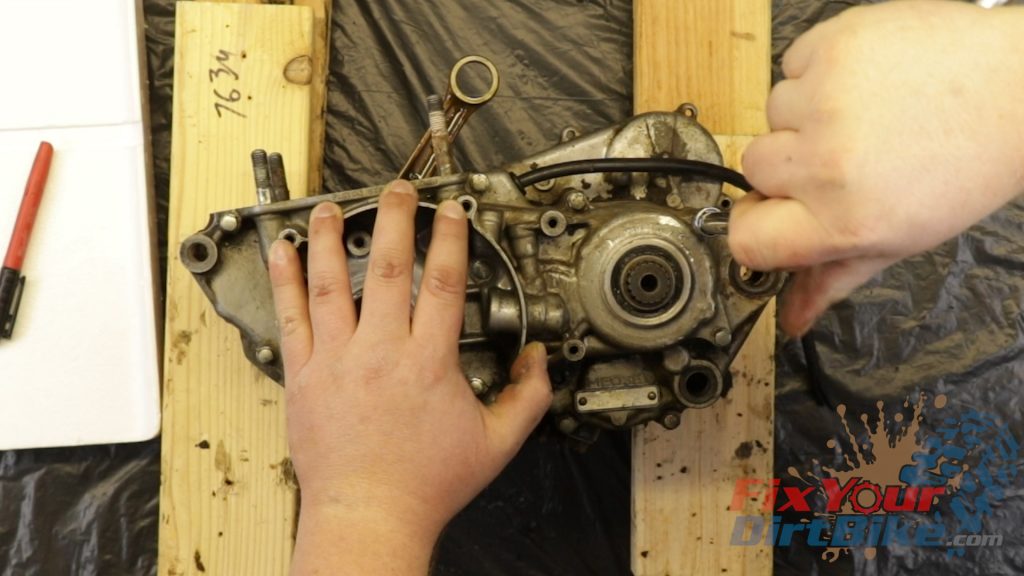

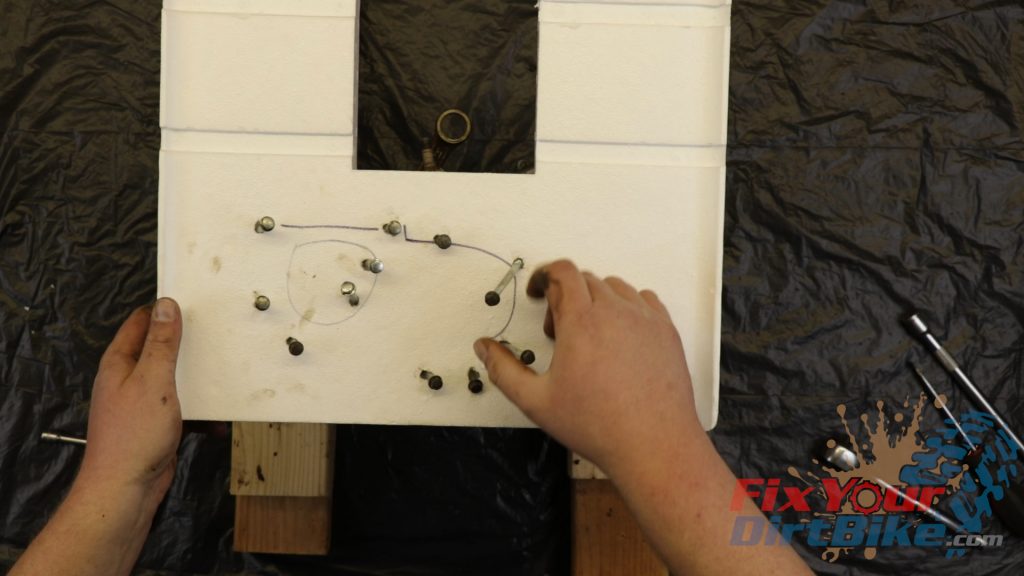

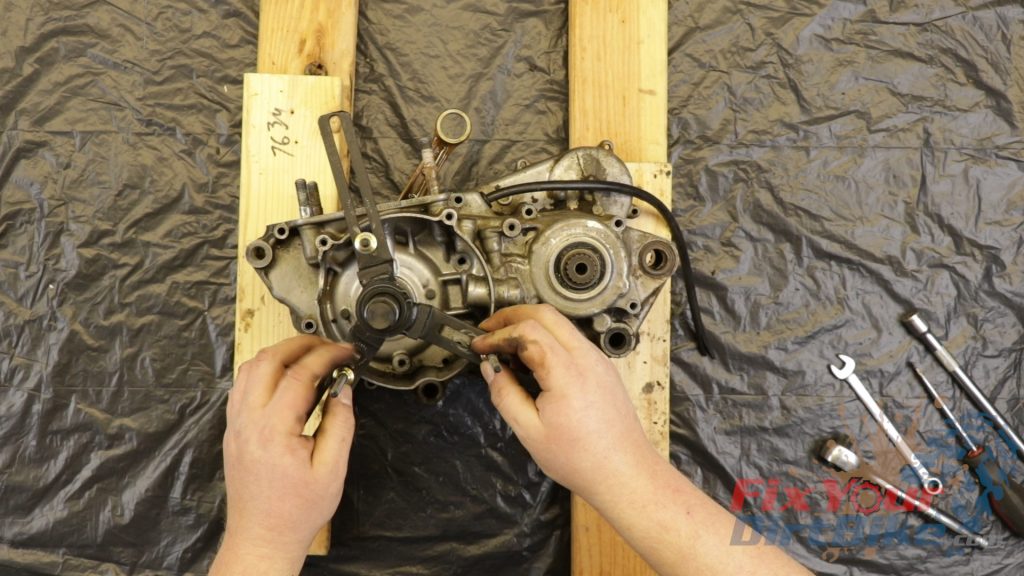

- Lay your crankcase on your blocks with the left side facing up. Loosen the 11 crankcase bolts in a crisscross pattern, ¼ turns at a time until they are all loose.

- The crankcase bolts vary in length, so outline the case on cardboard or styrofoam and place your bolts accordingly.

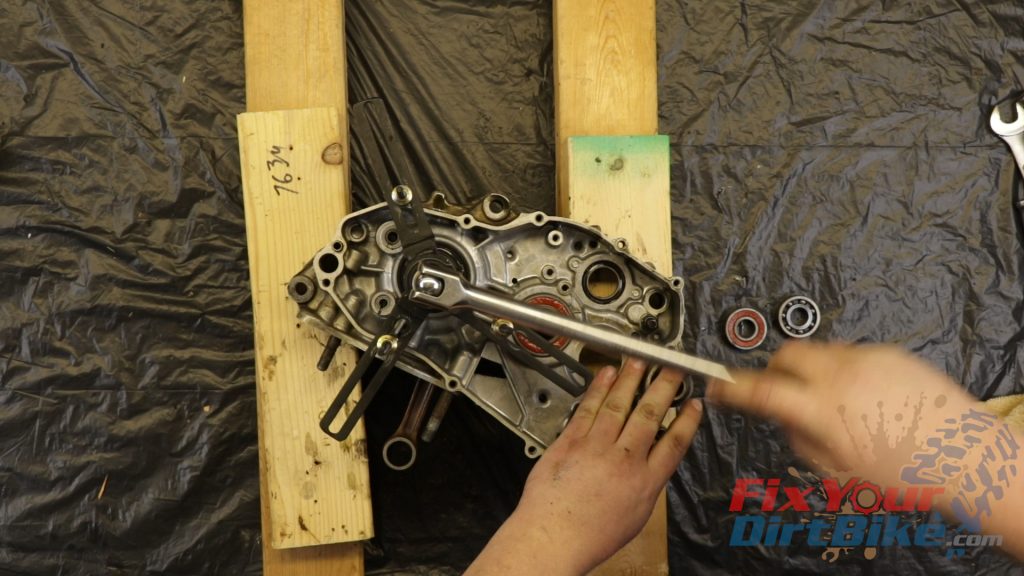

- Assemble your crankcase splitter and attach it to the case.

- Remember to keep the splitter parallel to the case.

- Begin tightening the splitter nut.

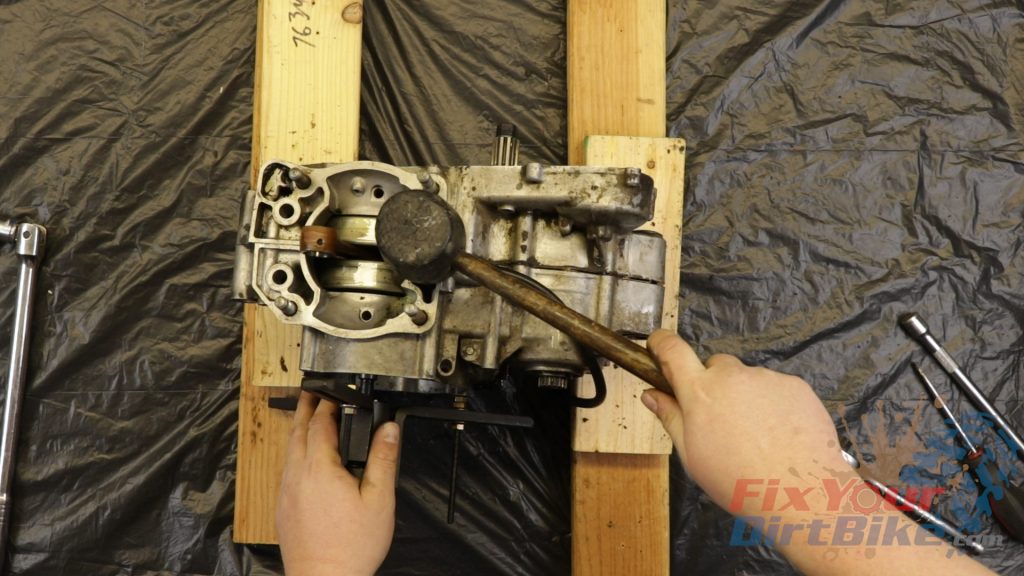

- After every turn, firmly tap the case seam with a rubber mallet. Make sure to check the case gap frequently. Ifif the case is separating unevenly, back out the splitter nut to remove pressure from the case. I had to tap aggressively on the front of the case where a dowel had seized.

- Remove the two alignment dowels, o-ring, and gasket material with the cases separated.

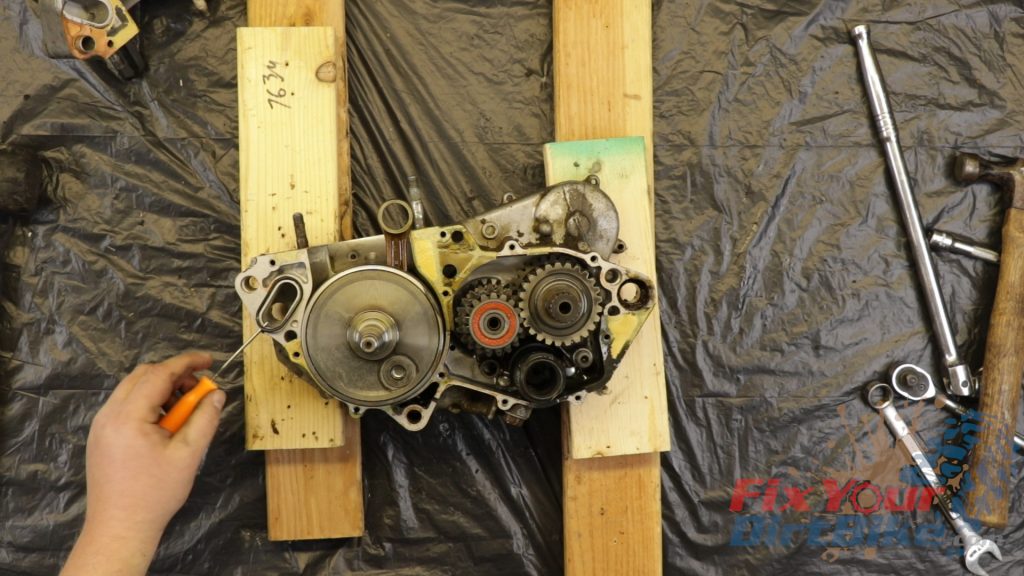

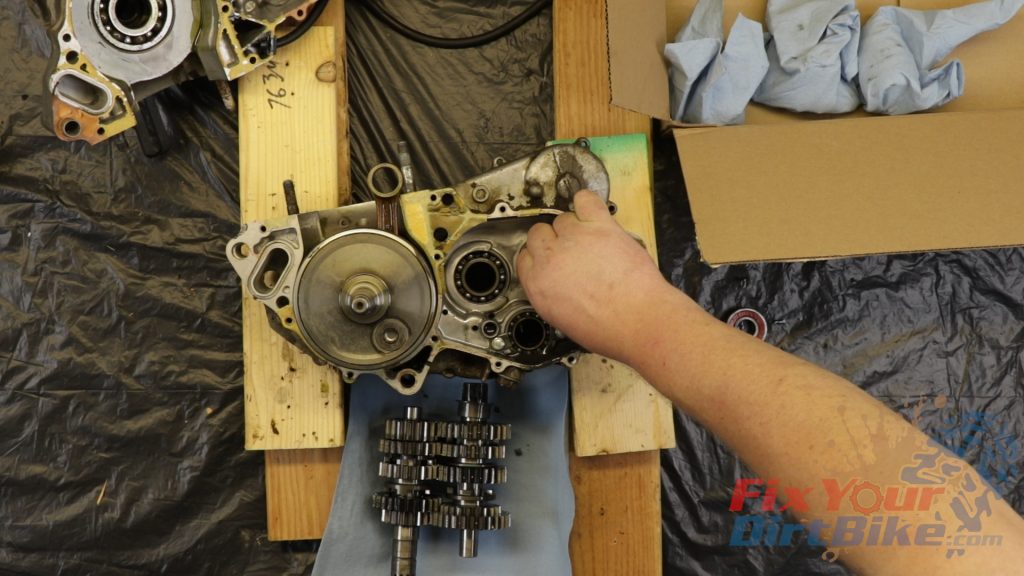

Transmission Removal

- Take every precaution you can when handling the transmission. Keep it oiled, wrapped, and clean at all times.

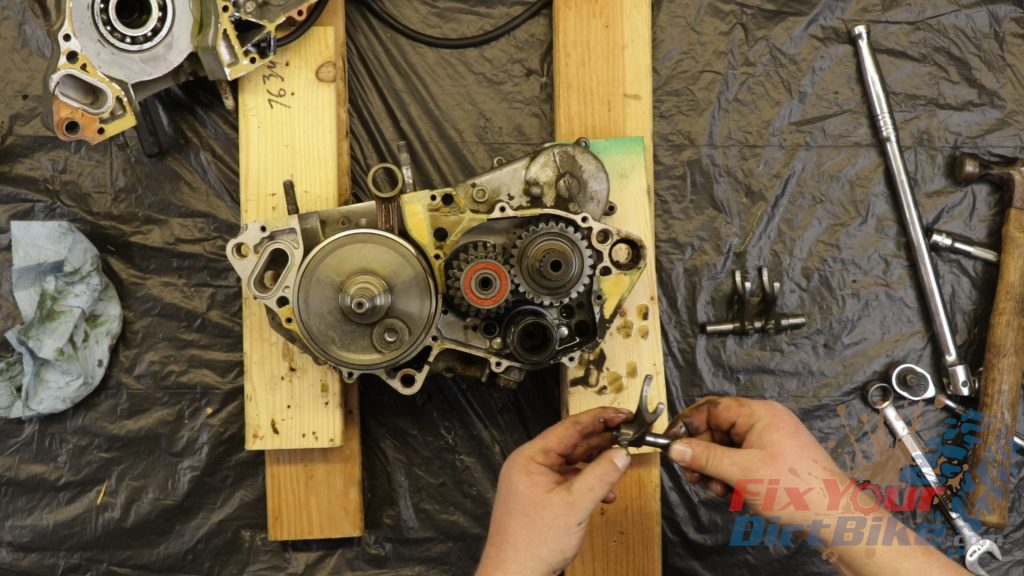

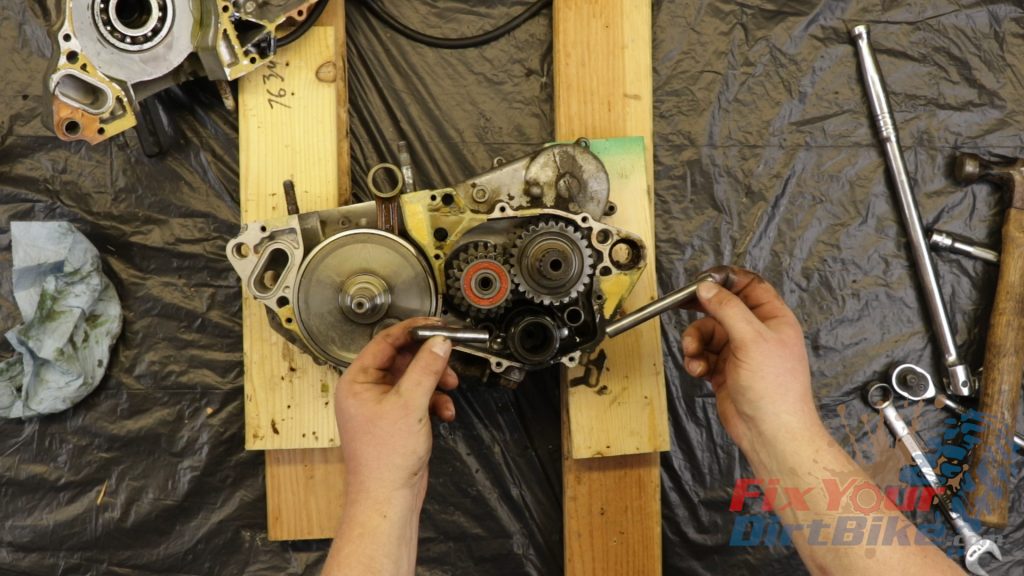

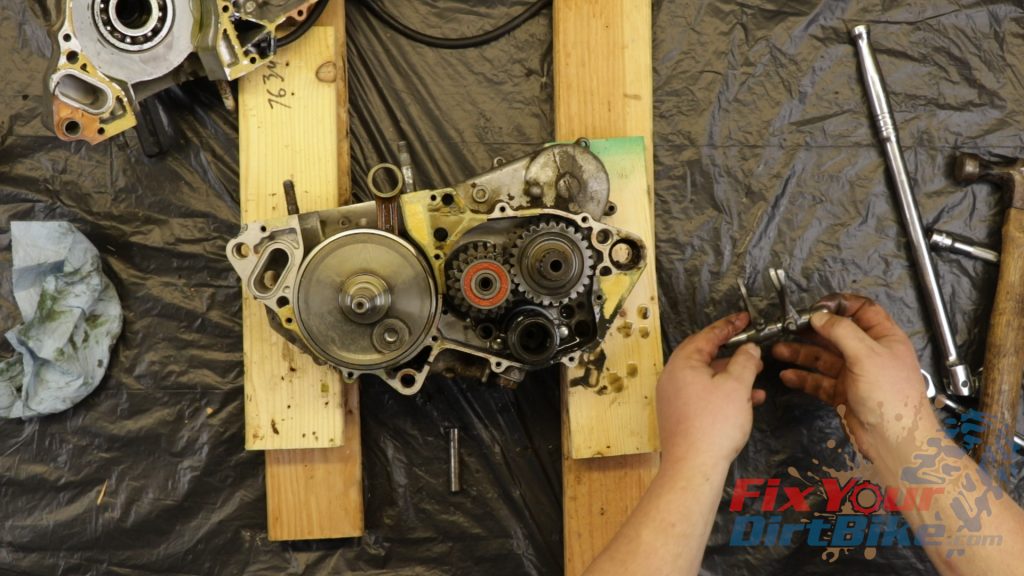

- Remove the two shift fork shafts and the shift drum and forks.

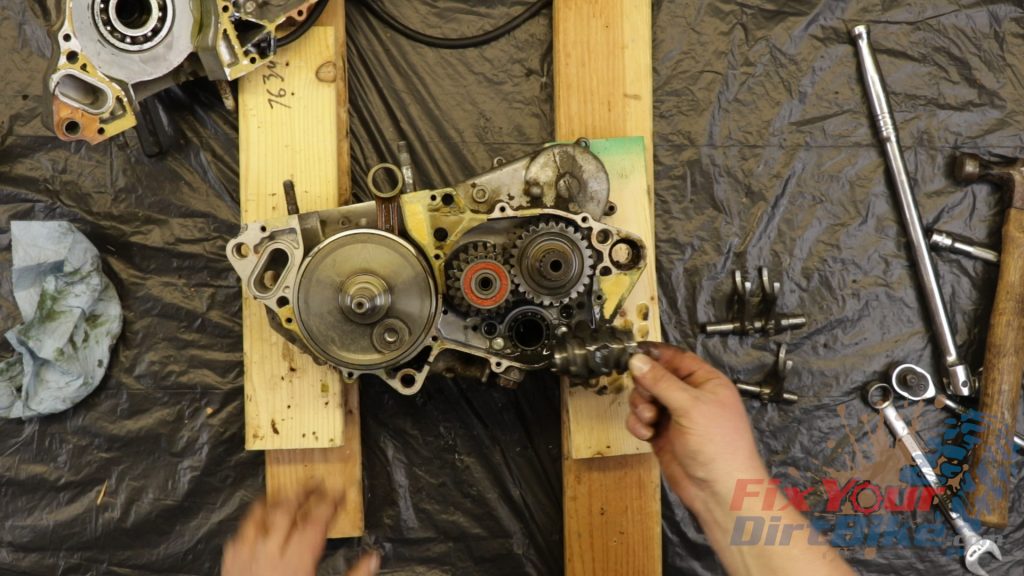

- Remove the main shaft and countershaft, keeping the gears meshed.

- Wrap the assemblies in a towel and set them aside.

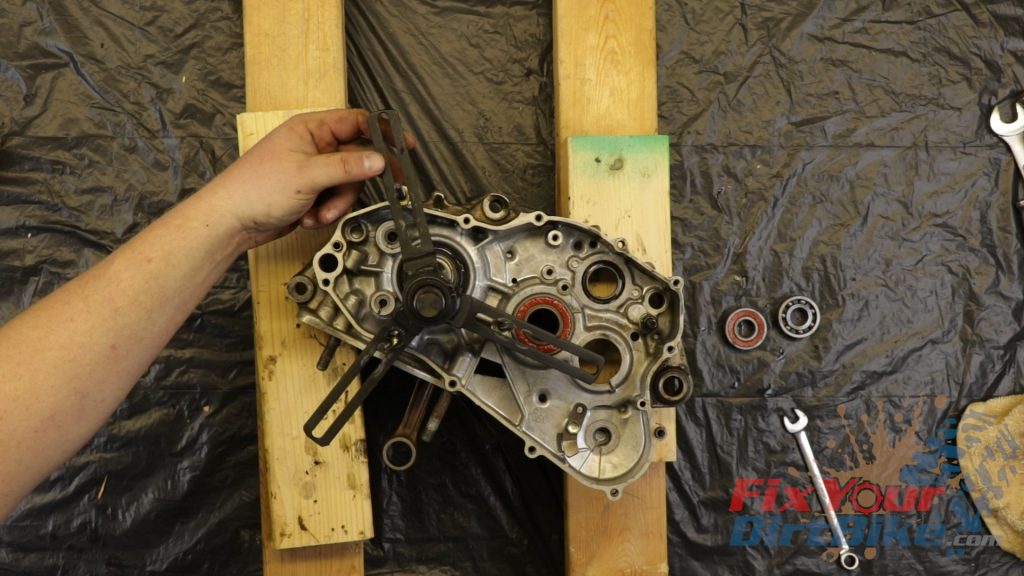

Crankshaft Removal

- Flip the right crankcase so the outside faces up, and place a layer of towels under the crankshaft. Attach the crankcase splitter with WASHERS… and press the crankshaft out of the case.

- Again, remember to keep the splitter parallel to the case.

- If your main shaft bearing comes out with the crankshaft, yomustto use your bearing splitter to remove the bearing from the shaft.

Clean & Inspect

- The mating surfaces must be spotless and smooth to ensure a tight seal. Remove all gasket material from the mating surfaces with part cleaner and a plastic scraper. With the big pieces gone, move on to the tough spots with a flat razor, taking extra care not to gouge the surface.

- With all the gasket material gone, give the surface a once-over with a fine-grit sanding disk. If you don’t have a Dremel, 600-grit emery paper will work just fine. When you are done, you want to have a smooth, almost mirror-like finish.

- This case has quite a few rough spots left over from casting. I have the equipment and the time, so I will smooth those out while I have the opportunity.

Related: How to service the rear swingarm bearings on your 97-01 Honda CR250.

Related: How to service the rear swingarm bearings on your 97-01 Honda CR250.

Remove Seals

- Remove the oil seals from the crankcase. Make sure to use a towel to protect the body.

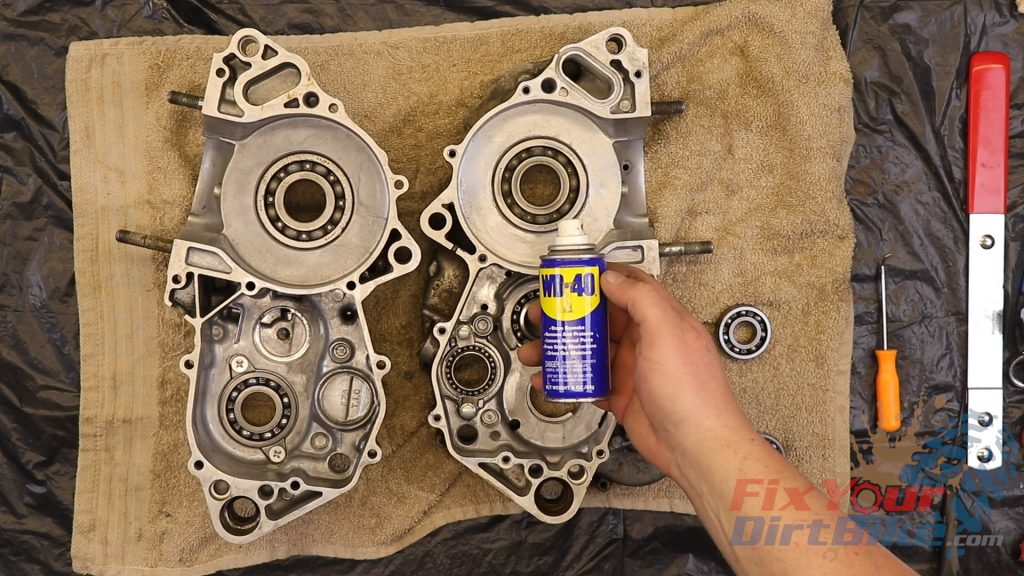

- Thoroughly wash the crankcase with water and solvent, dry it thoroughly with compressed air, and coat it with WD40.

Inspect

- With your case clean and shiny, check for any unusual wear or cracking. Inspect the crankshaft for cracks, rubbing, pitting, and heat damage.

- Check the connecting rod for play.

- If something doesn’t look right, take your crankshaft to a machine shop or dealership to have the runout and connecting rod radial clearance checked.

- This crankshaft is nonrepairable; if it is out of spec, you must replace it entirely.

Keep Your ’97-’01 CR250 Running Right!