How To Service The Steering Stem Bearings On Your 97-01 Honda CR250

You will need three specialty tools for this service: a steering stem nut adjustment wrench, a DIY bearing press, and a metal pipe that matches the diameter of the inner bearing race but still fits over the steering stem.

A steering stem wrench goes for around $13. You can make your bearing press out of grade 8 bolts and washers for about $15, and the pipe will cost between, $10 to $25, depending on the store.

The Tools You Will Need Are

- Steering Stem Adjustment Wrench

- Smackin’ Pipe

- Bolt Press

- Torque Wrench

- Breaker Bar

- 32mm Socket

- 10mm Socket

- Long Flat Screwdriver / Blind Bearing Puller

- Chisel / Dremel

- Gloves

- Grease

The Parts You Will Need Are

- New ’97-’01 Honda CR250 Steering Stem Bearing Kit

- Lithium EP Grease

Pre-Service Notes

- Start with your bike on a stand with the front end completely stripped except for one fork.

- I recommend opening the Service & Torque Specs in a new tab for easy reference.

- If you need parts and tools, make sure to buy them here!

- Pictures with captions are after the steps below.

- If you need any help don’t hesitate to ask!

Steering Stem Removal

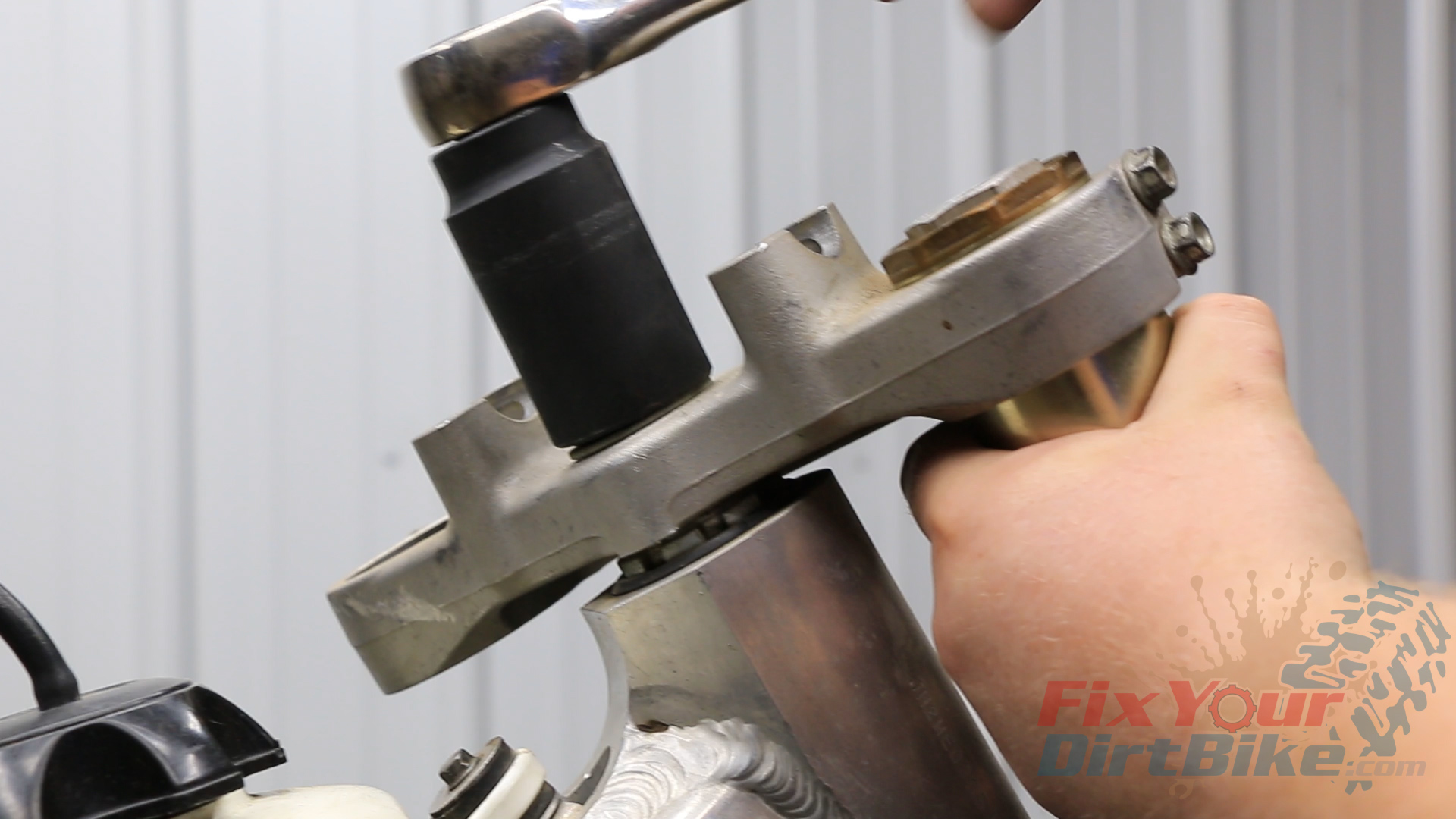

- Loosen and remove the steering stem nut and washer, then remove the other fork.

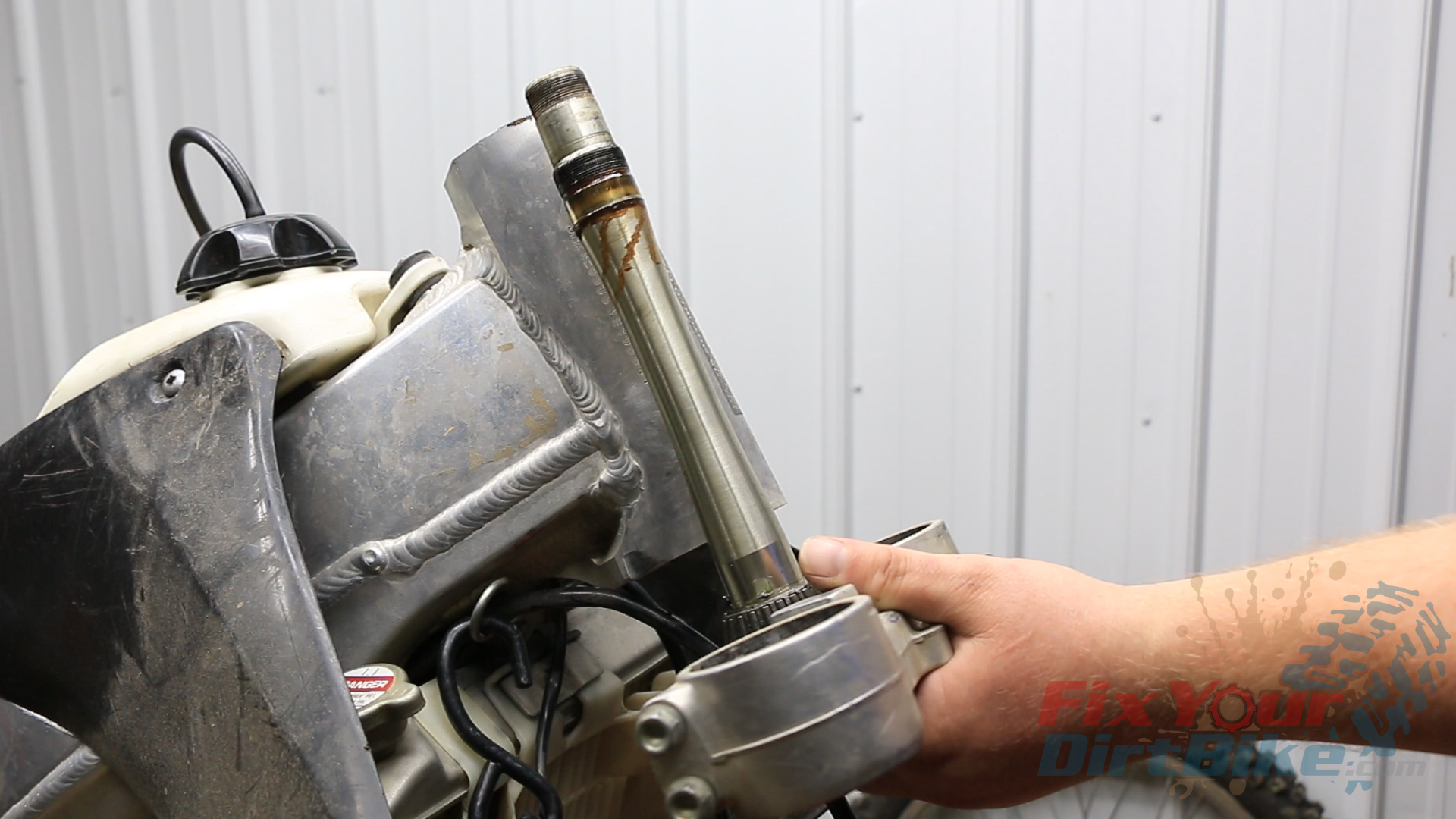

- Loosen and remove the steering stem adjustment nut, and lower the steering stem out of the steering head.

Related: Front-wheel bearing service for your 97-01 Cr250.

Related: Front-wheel bearing service for your 97-01 Cr250.

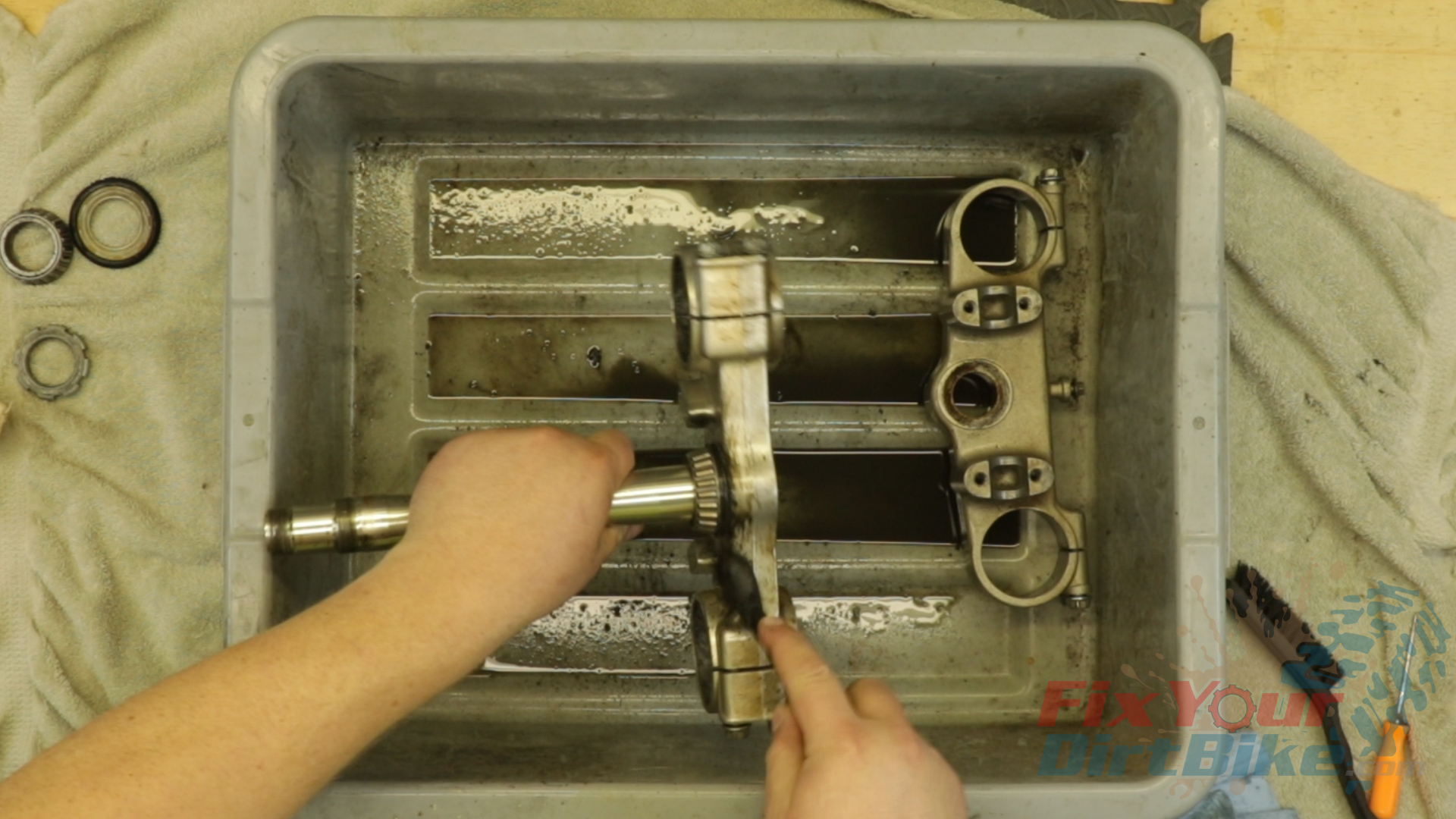

Clean & Inspect Your Steering Components

- Clean all components and check for obvious damage or wear to the bearings and welds.

- DO NOT REMOVE THE LOWER BEARING until you have cleaned and inspected it. Clean and inspect the steering head. The bearings are two pieces, with the outer race mounted inside the steering head.

- DO NOT REMOVE THE OUTER RACES FROM THE STEERING HEAD until you inspect them. You want to look for damage in the bearing races, and the welds connecting the head to the frame.

Steering Stem Bearing Replacement

These bearings and races on my 1997 Honda CR250 are in surprisingly good condition, so I am not going to replace them. Instead, I’m going to show you on my 2009 CRF450r. While the bearings are slightly different, the procedure is the same.

The outer races are pressed into the steering head, and the lower bearing is pressed onto the steering stem.

Bearing Removal

- You will need a sharp screwdriver or chisel to remove the lower bearing from the stem.

- If you try to hammer the bearing down off the stem, you will only catch the seal ring or crush the outer cage. Instead, hammer your chisel between the bridge and the bearing, and work your way around.

- The chisel and hammer should separate the bearing from the bridge, but it probably won’t. As with most worn out parts, this bearing refused to budge, so I moved to a Dremel with a cut off wheel.

- This cut is tricky because you can not get a perpendicular angle to the bearing. So start with a parallel cut about 2mm from the bridge, then make two cuts in a V shape between the edge of the bearing and the parallel cut.

- Obviously, this is not ideal, but if you take your time and watch your depth, you will be fine.

- I got a little too deep on my V cuts, but it wasn’t anything some light sanding and polishing couldn’t fix.

Outer Race Removal

- The outer bearing races have a small lip that sticks out inside the steering head.

- Take a screwdriver, or another long flat tool, and hammer the race out of the steering head, making sure to work around the race as you go.

- The outer race is another example of old parts not cooperating, so I used a blind bearing puller to remove these.

- If you don’t have a blind bearing puller set, you do not need to buy one. Most chain auto parts stores have loaner tools available with a refundable deposit.

- With the outer race removed, inspect the race bores. If the edges and surfaces are anything but smooth, correct the damage before installing the new races.

Related: Rebuild your rear shock linkage on your 97-01 Honda CR250.

New Steering Stem Bearings

I will be installing an All Balls bearing kit. This kit includes new bearings, outer races, and seals.

Bearing Installation

- Slide the new seal onto the steering stem with the wide side facing away from the bridge, followed by the bearing with the small side facing away from the bridge.

- Drive the bearing home with your metal pipe and hammer.

Outer Race Installation

- Place your new bearing race in the bore with the wide side facing out.

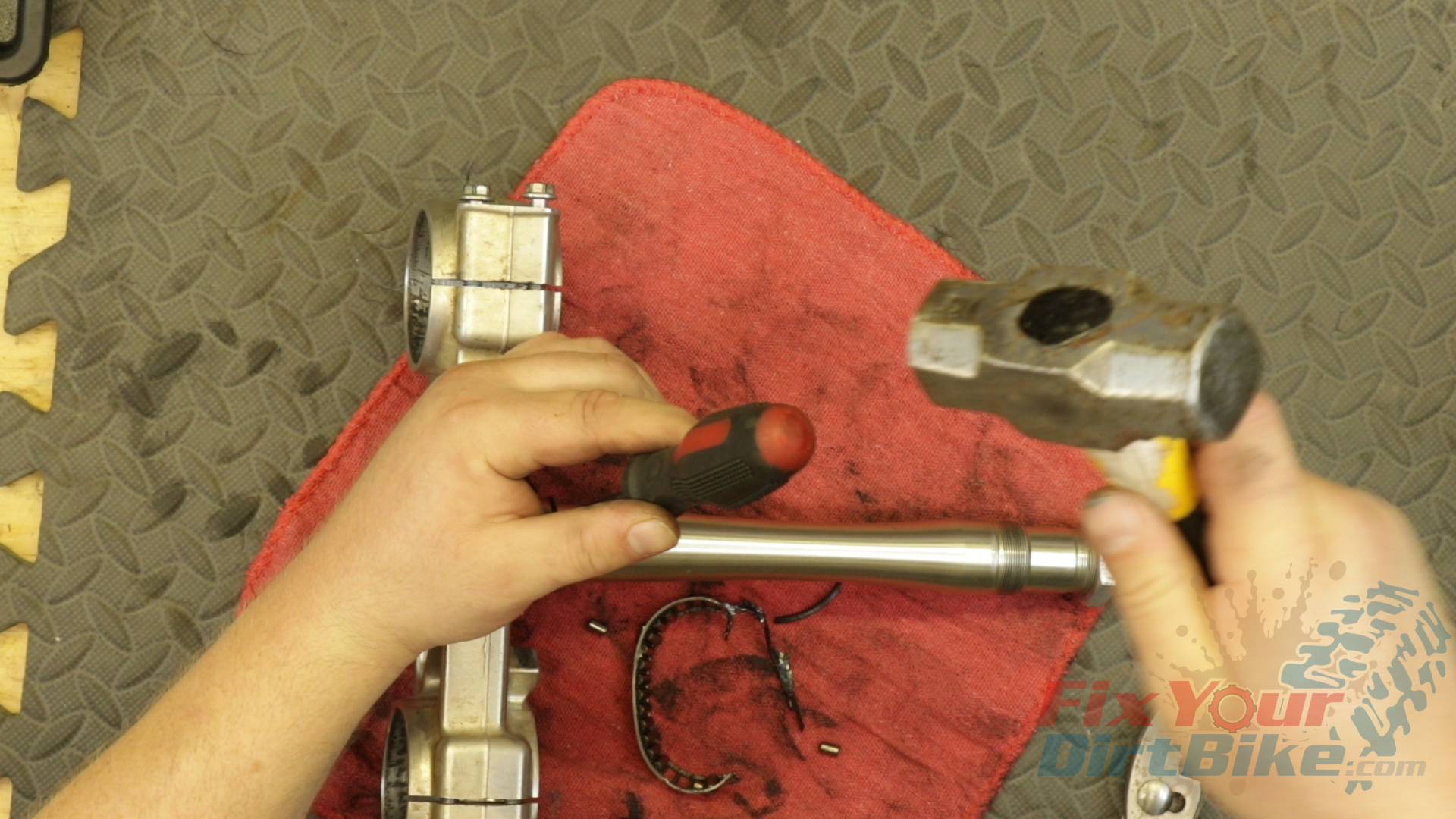

- Assemble your bearing press with the bolt head on the side you are pressing. You will have to get creative with the spacers on the nut side. For example, I like to use the top bridge as a spacer because it rests flat on the bottom of the steering head.

- On the bolt side, you need to find a washer that will fit over the race but still, clear the outer bore. As with most bearings, some slight adjustments may be needed to keep everything aligned.

- Press the bearing into the bore.

- These bearing races are NOT an interference fit so that they will press in easily. If you are forcing them in, something is wrong, so reset and try again.

- Run your fingernail along the bottom side of the race to check for any gaps. My race did not press into the bore completely, but I was able to correct that with a large socket and hammer.

- Repeat with the bottom race.

Related: How to serice the swingarm on your 1997-2001 Honda CR250

Steering Stem Installation

Choosing The Propper Grease

- Steering stem bearings require an EP grease. The EP stands for Extreme Pressure.

- But since there is very little heat in the steering head, the grease can’t be too thick, or it will not move around the bearings.

- Moly based greases provide the best protection under extreme load, but they are also incredibly thick.

- General-purpose grease is the right consistency but provides inadequate pressure protection under load.

- I find that a Lithium-based EP grease provides the proper level of protection at the right consistency.

Install The Stem

- Apply a thick layer of grease around each bearing and outer race. When I say thick, I mean THICK, you want as much grease in those rollers as possible.

- Install the top seal with the wide side facing down.

- Install and tighten the adjustment nut until it is bottomed out.

- With the nut tight to the seal, work the stem back and forth. This will disperse the grease, and allow you to check for any rough spots.

- Loosen the nut to the point where the steering stem rotates freely with no play.

- Install the forks, but only tighten the upper pinch bolts.

Install The Steering Stem Nut; Torque To

- 108 ft-lbs on 97-2000 models

- 80 ft-lbs for 2001 models

Recheck the rotation; You should still be able to rotate the stem freely with no play.

Recheck the rotation; You should still be able to rotate the stem freely with no play.

Assemble your front end and ride around for about 30 minutes.

Related: 97-01 Honda CR250 bottom end service.

Steering Adjustment

- After your break in ride, put your bike on a stand and check your steering stem bearing adjustment.

- With the wheel facing forward, you should be able to tap the fender left or right with front end rotating to lock under its own weight. This is the correct adjustment.

- If the front end does not turn freely, the adjustment nut is too tight.

- Push and pull the forks; if you feel anything moving in the steering head, the adjustment nut is too loose.

- To correct the adjustment, loosen the lower fork pinch bolts, loosen the steering stem nut, and turn the adjustment nut ¼ turn, then re-torque the steering stem nut.

- Repeat this process until you reach the proper adjustment, the re-torque your lower bridge pinch bolts.

If you have any questions about this shock link service, please let me know in the comments or on social!

Back To 1997-2001 Honda CR250 Master Repair Index