What Is Oil Film Strength? Why Do I Care?

Film strength. We’ve all heard of it at some point, but most of us aren’t exactly sure what it is, or what it does for our dirt bike engines. We know that it has something to do with oil, but that’s about it. In this article, I’ll try to answer the previous questions and take the mystery out of oil film strength.

What Is Film Strength?

The simple answer is that film strength is protection for the components of your engine.

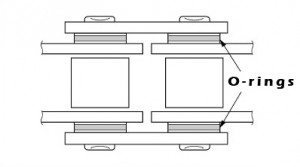

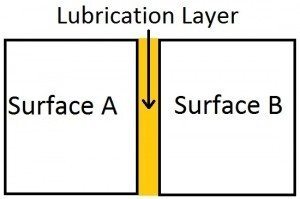

The more in-depth answer starts with a basic definition of film strength. Oil film strength is a measurement (in psi) of a lubricant’s strength, or its ability to not break under pressure. Oil’s primary job is to prevent the various components of engines from rubbing against each other. When oil doesn’t do its job, friction is created, and the parts of your engine can become damaged over time as a result. However, if an oil has a high film strength, it can sustain its position between the two components without being squeezed out, hence giving the components the necessary protection they need from each other.

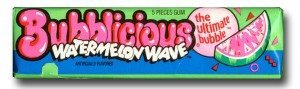

Film Strength & Bubble Gum

I like to relate the properties of film strength with that of blowing bubbles with bubble gum. A low oil film strength is like trying to blow a bubble with just one piece of bubble gum. The pressure from the air used to blow the bubble will only allow the bubble to barely start to take form before it pops. The layer of gum is too thin to sustain higher pressures of air.

Now, imagine taking five pieces of bubble gum in your mouth at one time and then attempting to blow a bubble with them. That bubble is going to be able to withstand a lot more pressure without breaking than the single piece of bubble gum could. The reason it’s able to do that is that it’s more resistant to the pressure, due to the thickness provided by combining five pieces of gum into one. This is similar to oil with a high film strength. It can tolerate a lot more pressure before breaking and being squeezed out from between the two metal components.

Strength Of Various Oil Types

Film strengths vary in different oils. Some oils have ridiculously high film strengths, while other oils have ridiculously low oil film strengths. It’s important to take each into account when choosing an oil type for your bike.

Full Synthetic Oil

Full synthetic oils have the highest film strengths from 2000 psi to 5000 psi. This is because synthetic oils are chemically constructed. This means that certain “modifications” can be made to alter the oils’ film strength during production.

Blended-Synthetic Oil

It follows close behind its cousin (full synthetic) in film strength, sometimes reaching the same measurements.

Castor Oil

Castor oil is another oil that possesses very high oil film strength measurements. However, the unfortunate by-product of castor is that you get some wax and sludge build-up as well.

Related: Make sure you are using the right oil, not knowing could cost and engine!

Mineral Oil

Mineral oil is the one dominant type of oil that continually sees low marks in the film strength category. Typical, straightforward mineral oil will measure between 500 – 900 psi.

A good rule of thumb to take into consideration when figuring out how high the film strength measurements would be without knowing the exact number is to look at the oil’s viscosity and thickness. Higher viscosity and thickness translates into higher oil film strength, A lower viscosity and thinness translates into lower film strength. But remember, when comparing motorcycle oil to car oil, everything changes because car oil is designed to serve an entirely different purpose.

Final Thoughts

Just like with any mechanical marvel, a dirt bike’s engine has to operate at optimal levels at all times to ensure longevity and excellent performance. A key component to achieving that is making sure you’re putting the best oil possible into your motor, whether it is a 2-stroke or 4-stroke.

Oil film strength is just one of the many components of oil that can’t be overlooked when deciding on which type/brand to use on your bike. It is decisions like these that can make all the difference when its time for a rebuild, because replacing your whole dirt bike engine is a lot more expensive than a routine rebuild.

If you have any questions or anything to add, please leave them in the comments or on our FaceBook page!

Keep Reading – Can You Trust Your 2-Stroke Injection System?

Related:

Related:

First, we need to define the term biodegradable. Biodegradable means that the substance (or object) can be broken down and consumed using bacteria or other living organisms. In other words, if something is biodegradable, it can be reabsorbed into the environment.

First, we need to define the term biodegradable. Biodegradable means that the substance (or object) can be broken down and consumed using bacteria or other living organisms. In other words, if something is biodegradable, it can be reabsorbed into the environment.

Short Review:

Short Review: