Front Wheel Bearing Replacement

Replacing the front wheel bearing set on your ’97-’01 Honda CR250 is a very simple job. The bearings are a driven fit, so you will need to remove them with a torch and patience.

The Tools You Will Need

The Tools You Will Need

- A Long Drift

- Tire Spoon

- Big Hammer

- Regular Hammer

- A socket that matches the INSIDE bearing race diameter

- A Socket that matches the OUTSIDE bearing race diameter

- Socket Wrench Extension

- Propane Torch

- Two long 2x4s

- Block Of Wood

- Rubber Gloves

- Work Gloves

- Safety Glasses

Front Wheel Bearing Replacement Parts

The parts you will need are a set of New ’97-’01 Honda CR250 bearings (Amazon.com) and seals, and a bucket of grease.

I will be installing a new set of Factory Links bearings and seals.

These bearings come pre-greased and double shielded, and the seals are reinforced with an internal tension spring.

I highly recommend this Factory Links bearing and seal set, and they go for about $20 on Amazon if you don’t have yours yet. (It looks like Factory Links are unavailable right now, so I linked to another brand I trust).

The grease I will be using is general-purpose automotive grease from the 1980s, and you can get yours from your grandpa’s garage or get some sweet Lithium high-pressure Maxima Racing Grease.

It always helps to know what you’re working on before you get to it, so make sure to see how your front hub works before you start on the bearings.

You Can Get All The Parts And Tools You Need At Amazon.com!

Pre-Service Notes

- Unlike the rear wheel, you can start with either side of the front wheel hub. In this walkthrough, I will begin with the left bearing.

- I recommend opening the Service & Torque Specs in a new tab for easy reference.

- If you need parts and tools, make sure to buy them here!

- Pictures with captions are after the steps below.

- If you need any help don’t hesitate to ask!

Related: When you’re done with the front bearings, keep the party going in the rear!

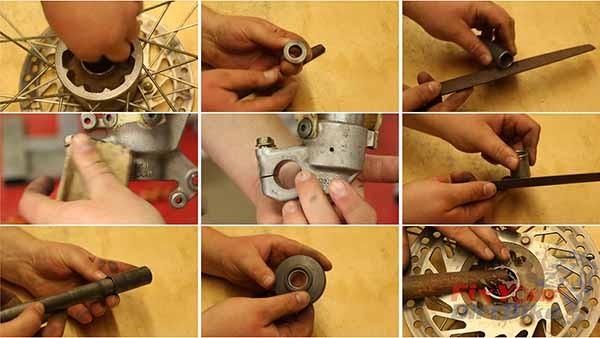

Front Wheel Bearing Removal

- Step 1: Pry out the old seals.

- There will be a small lip inside the seal. Hook that lip with your tire spoon to pry it out.

- Step 2: Dislodge the distance collar.

- Insert your drift from the right side of the hub up to, but not touching, the left bearing.

- Step 3: Work your drift up and down to push the distance collar away from the inner bearing race.

- Step 4: Find a sturdy surface.

- You will be hammering your bearings out, so make sure you are on a solid surface.

- Place your wheel on your 2x4s with the left bearing facing UP.

- Make sure the rim and tire are the only part of the wheel touching wood.

- Step 5: Remove the first bearing.

- Heat the hub with your propane torch. This will let your hub expand and take the pressure off of the bearing.

- Work your torch around the hub, keeping the heat even as you go.

- Heat the hub for around 60 Mississippi.

- Step 6: Flip your wheel over, place a socket over the INNER bearing race, and hammer the opposite bearing out.

- Your bearings may come out in one piece, or they might shatter as this one did.

- Step 7: If the other bearing is still intact, repeat the heat and beat process.

Hub Maintenance

- Step 8: Inspect each part of the hub assembly for wear, pits, or burs. If you find any rough areas, file them down to smooth.

- DO NOT remove material from the ends of the distance collars.

- They need to stay an exact length. If the ends are damaged, replace the collar.

- Step 9: After you have removed any damage, sand every hub component with 220 grit sandpaper to ensure every contact surface is as clean as possible.

- Step 10: Take your new bearings, and make sure they DO NOT fit. These bearings are a driven fit, so if they slip into the hub on their own, the hub is worn and needs to be replaced.

- In this case, the left side bore is a loose fit at first but tightens up farther in. This will still work, but this is probably the last bearing change for this hub.

Related: Keep the bearing train rolling with this steering stem bearing service!

Front Wheel Bearing Installation

If you go with single shield bearings, you will need to grease them before installation, and the shielded side will face out.

Throughout this install, you will need to grease the hub between every step.

- Step 11: Place your wheel on a block of wood, so only the hub is supported.

- Step 12: Position your bearing flush against the hub.

- Step 13: Use a socket that is big enough to match the OUTER bearing race, but will still fit into the bore to start tapping the bearing into place.

- Once the bearing starts to seat, make sure it is square to the bore. Adjust the bearing with light hammer taps as needed.

- Drive the bearing until it is seated in the bore.

- Step 14: Flip your wheel and insert the distance collar.

- Step 15: Repeat the driving process until the top of the second bearing is flush with the bore.

- Step 16: Insert the axle into the opposite side of the hub to align the collar with the bearings.

- As you can see, the axle is too long for a socket, so build up a base with wood to support the hub and let the axle sit lower.

- Make sure the axle is still tight in the collar and bearings.

- Step 17: Drive the bearing into the bore, then remove the axle.

- Step 18: If your seals contain a retaining spring, make sure it is facing in and drive your new seals until they are flush to the hub.

- Remember to take your time, and your bearing replacement will be easy.

If you want to help take Fix Your Dirt Bike to the next level, check out my Patreon page!

If you have any questions or anything to add, please leave them in the comments or on our FaceBook page!