How To Calculate Top End Engine Clearances On Your 97-01 Honda CR250

The Tools You Will Need:

The Tools You Will Need:

- Paper

- Pencil

- Math

- (Master Tools & Parts List Below)

Before we can calculate clearances, we need to identify the cylinder. Honda produced two variations of this cylinder, A and B. You can find A or B stamped on the rear mounting hole on the left side of the cylinder.

Pre-Service Notes

- I recommend opening the Service & Torque Specs in a new tab for easy reference.

- If you need parts and tools, make sure to buy them on Amazon!

- Pictures with captions are after the steps below.

- If you need any help don’t hesitate to ask!

Piston Measurements

We already calculated the groove and pin clearance in the piston inspection video, so now we need to measure the outside diameter of the piston perpendicular to the wrist pin bore.

- The diameter of the piston should be no LESS than 2.609 inches for both A and B cylinders.

- My piston measured at 2.607, so it is out of spec by .002 inches.

- We will also use this measurement to calculate the maximum Piston to cylinder clearance.

Related: How to service the rear brake caliper on your 1997-2001 Honda CR250.

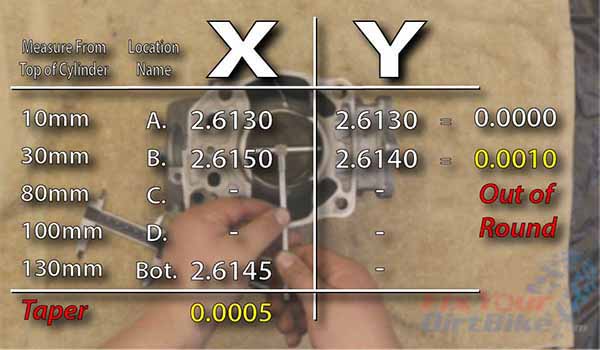

Cylinder Measurements

We are going to use the measurement we took earlier to determine three things:

- Cylinder Wear

- Cylinder Out Of Round

- Cylinder Taper

The wear limits for both A and B cylinders are no GREATER than 2.615 inches at its largest measurement.

This cylinder measured at 2.615, so I am just inside the wear limit.

The out of round limit is 0.002 inches.

Using the chart you made earlier, determine the out of round by finding the difference between X and Y for measurement points A and B.

This cylinder has no out of round for point A, and B is .001 inches out of round, which is within spec.

The cylinder taper limit is also 0.002 inches.

To find the cylinder taper, we will use column X.

Subtract the bottom number from either A or B, whichever one is larger.

This cylinder has a taper of .0005 which is also within spec.

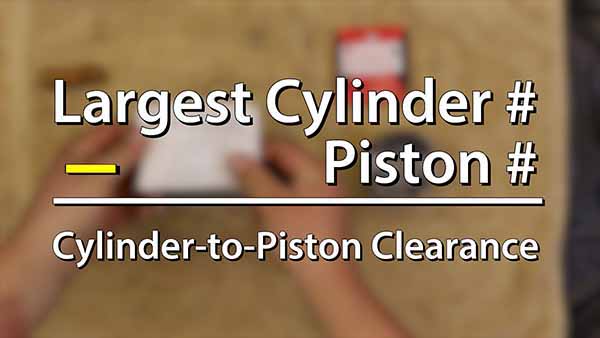

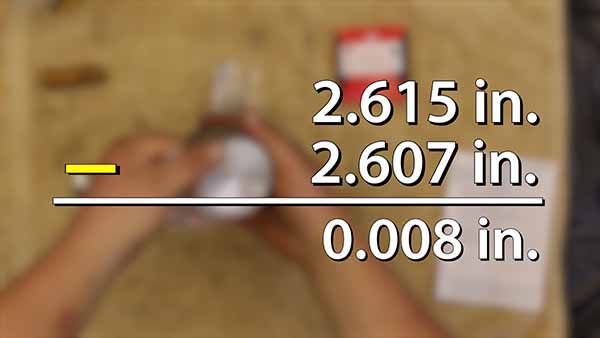

Piston To Cylinder Clearance

The piston to cylinder clearance must be no GREATER than 0.004 inches.

Take the piston diameter measurement, and subtract it from the largest cylinder measurement.

The largest measurement on my cylinder was 2.615 inches, and my piston measured at 2.607 inches, leaving me with a clearance of 0.008, putting me .004 thousandths of an inch out of spec.

The largest measurement on my cylinder was 2.615 inches, and my piston measured at 2.607 inches, leaving me with a clearance of 0.008, putting me .004 thousandths of an inch out of spec.

The new piston I will be using measured at 2.6125, bringing my clearance to .0025 inches, which is well within clearance.

The new piston I will be using measured at 2.6125, bringing my clearance to .0025 inches, which is well within clearance.

← Part 8: Exhaust Valve Inspection

Part 10: Exhaust Valve Installation →

Top End Rebuild Tools List: (Links to Amazon)

- Piston Pin Puller

- Piston Holder

- Machinists Straight Edge

- Feeler Gauges

- Telescoping Bore Gauges

- Digital Calipers

- Plastic Scraper

- Spark Plug Thread Follower

- Motion Pro Torque Wrench Adapter

- Molybdenum Grease

- Lithium Grease

Top End Rebuild Parts List: (Links to Amazon)

Keep Your ’97-’01 CR250 Running Right!

- Service Specification

- Clutch Replacement

- Carburetor Service

- Engine Top End

- Engine Bottom End

- Brakes

- Exhaust

- Front Suspension

- Rear Suspension

- Wheels & Tires

- Kickstarter Inspection

- External Shift Linkage