How To Inspect The Cylinder Head On Your 97-01 Honda CR250

- Plastic Scraper

- Soft Brush

- Shop Towels

- Spark Plug Thread Follower

- Metal Lubricant/Oil

- Machinists Straight Edge

- Feeler Gauges

- Emery Paper

- WD40

- Plastic Wrap

- (Master Tools & Parts List Below)

Pre-Service Notes

- I recommend opening the Service & Torque Specs in a new tab for easy reference.

- If you need parts and tools, make sure to buy them on Amazon!

- Pictures with captions are after the steps below.

- If you need any help don’t hesitate to ask!

Cylinder Head Cleaning

- Clean the entire head with parts cleaner and a soft brush.

- Clean the cylinder head mounting surface with a plastic scraper.

- If you have carbon buildup in the combustion chamber, soak it in parts cleaner, then gently scrub it off with a scouring pad.

- Clean the spark plug threads by threading a rolled-up shop towel through the hole.

- With the surfaced cleaned, inspect for any signs of obvious wear or damage

- Check the water jackets are free of obstruction, and the mating surface is smooth.

- You can smooth out small burs and pits with 600 grit emery paper, but be very careful, 1000th of an inch could take your head out of spec.

- Gently run your spark plug thread follower all the way through the spark plug hole to correct any potential misalignment.

- If your threads are stripped out and your follower cannot correct them, you will need to install a Helicoil.

Inspect The Cylinder Head for Warp

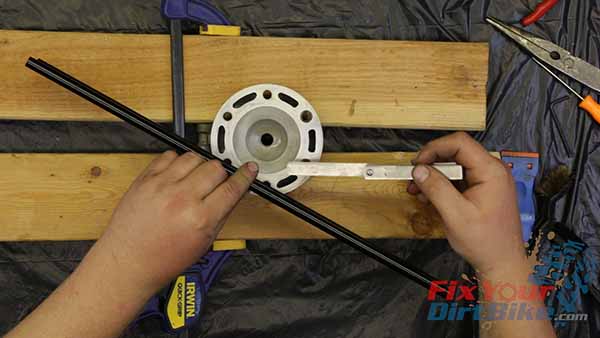

- Lay your straight edge across two adjacent mounting holes, and try to fit your feeler gauge underneath.

- If you find any gaps, double-check the head for smoothness, and try again.

- If the gap still exists, record the measurement.

- Repeat this measurement around the head.

- The warp limit for your cylinder head is two thousandths (0.002) of an inch.

How To Surface The Cylinder Head

- You may be able to bring your head into spec with a sheet of 600 grit emery paper.

- Tape the emery paper to a sheet of glass, and dampen with water.

- Run your cylinder head in a figure-eight motion against the paper, using light pressure.

- Stop and measure your clearance every 3 passes.

- If you cannot bring your head back to spec, you will need to take it to a machine shop.

- Clean your cylinder head with HOT soapy water, and rinse thoroughly.

- Dry with compressed air and double-check the mating surface for smoothness.

- If everything looks good, apply a light coat of WD-40 to avoid oxidation, and wrap your cylinder head in plastic wrap to avoid contaminants until you are ready for assembly.

- Finally, check the hanger plates for damage.

- If the plates are bent, or the holes are elongated, they need to be replaced.

- These have some dents on the top, but they are still straight with round holes.

Top End Rebuild Tools List: (Links to Amazon)

- Piston Pin Puller

- Piston Holder

- Machinists Straight Edge

- Feeler Gauges

- Telescoping Bore Gauges

- Digital Calipers

- Plastic Scraper

- Spark Plug Thread Follower

- Motion Pro Torque Wrench Adapter

- Molybdenum Grease

- Lithium Grease

Top End Rebuild Parts List: (Links to Amazon)

Keep Your ’97-’01 CR250 Running Right!